COOKWARE SETS

Mar 2023

In-house designed ceramic-coated cookware sets, from design to manufacturing.

Before Heading to the Design Phase

When I worked at a brand company, we followed clear brand guidelines and started each new product line by visiting suppliers to understand production limits, materials, and finishes. We then worked with other departments to check FOB prices and tooling lead times, so we could compare production options and choose the best solution. Once top management, sourcing, and R&D were aligned, we moved into the detailed design phase to develop the final product concept.

Why Ceramic, Why Better

Traditional non-stick cookware (Teflon) contains PTFE in its coating. While it is generally considered safe, it must be used with care. At temperatures above 260°C, the coating can break down and release harmful substances.

Ceramic-coated cookware offers the same non-stick performance without PTFE. Even when overheated, it remains safe, ensuring no toxic substances are released — making it a healthier choice for everyday cooking.

Handle Design Highlights

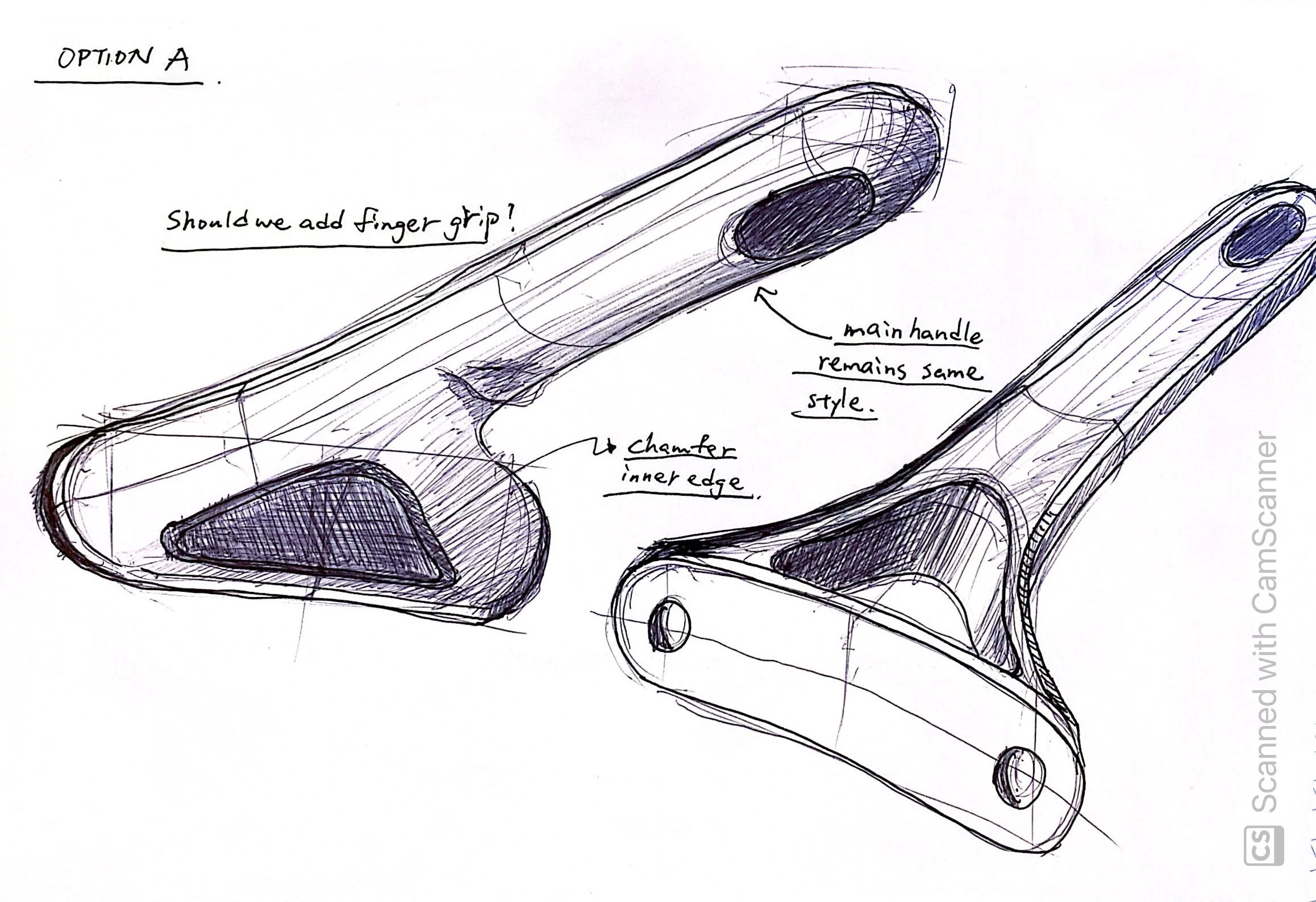

Ergonomic, durable, and thoughtfully designed with a groove that doubles as a utensil rest. We focused on creating a shape that reflects the brand’s values, integrates a practical utensil rest, and establishes a distinctive form to stand out from competitors. As the very first cookware set for Greater Goods, the design had to embody both functionality and identity.

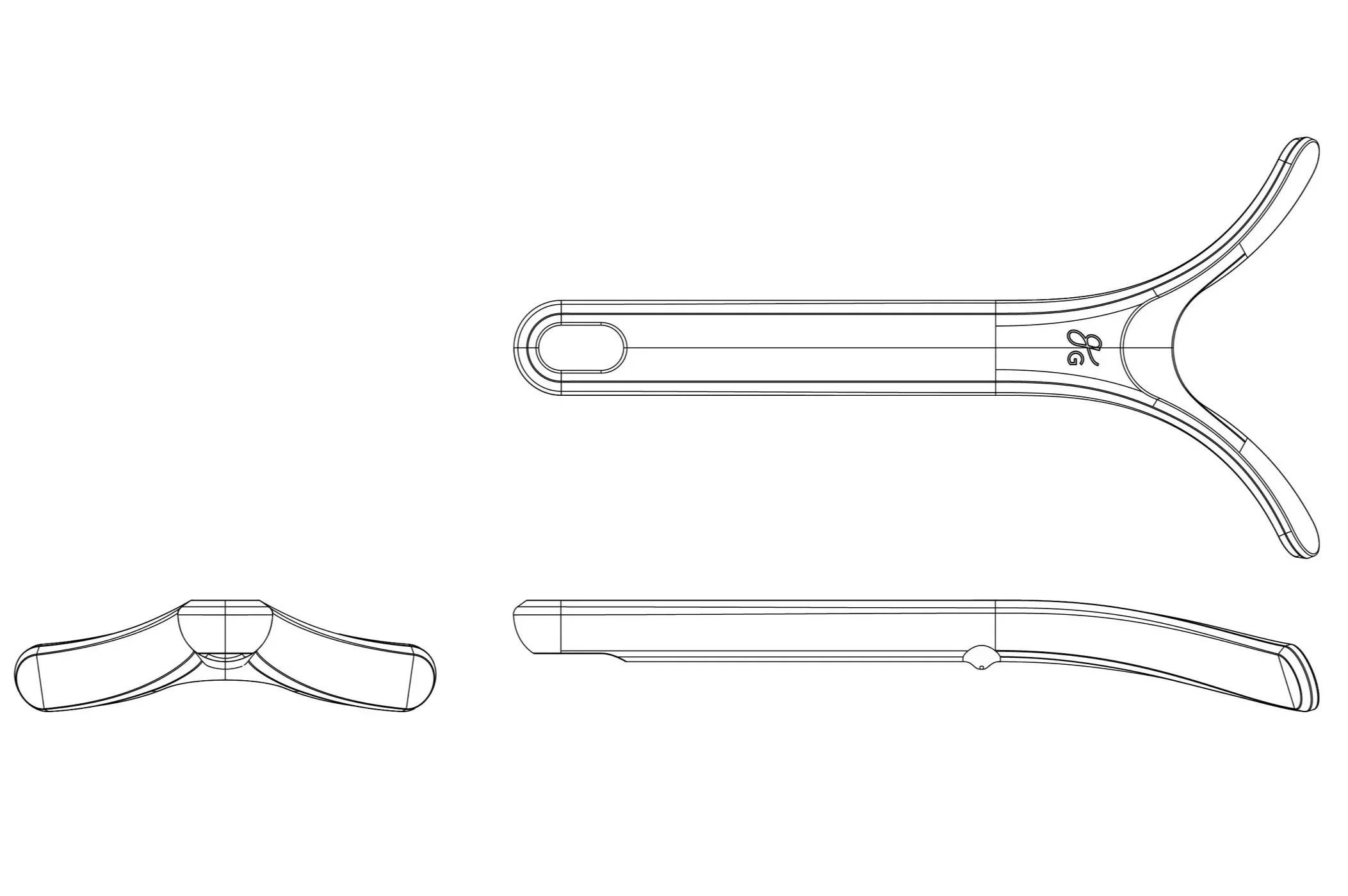

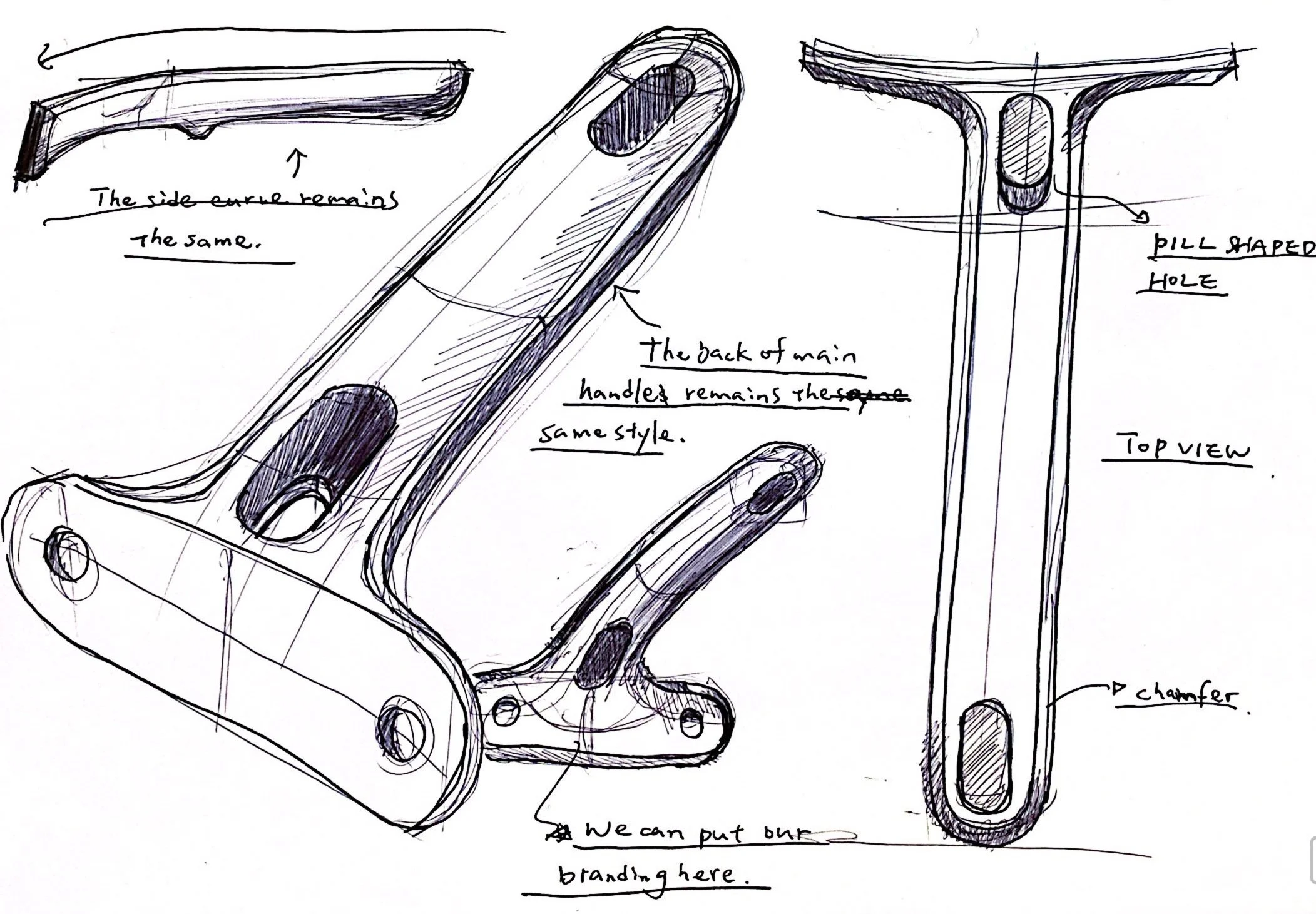

Handle Design

Greater Goods often uses pill-shaped forms as part of its design language, so we began with a geometric shape rather than an organic style. This approach not only differentiates the product from competitors but also reinforces brand identity and adds marketing value.

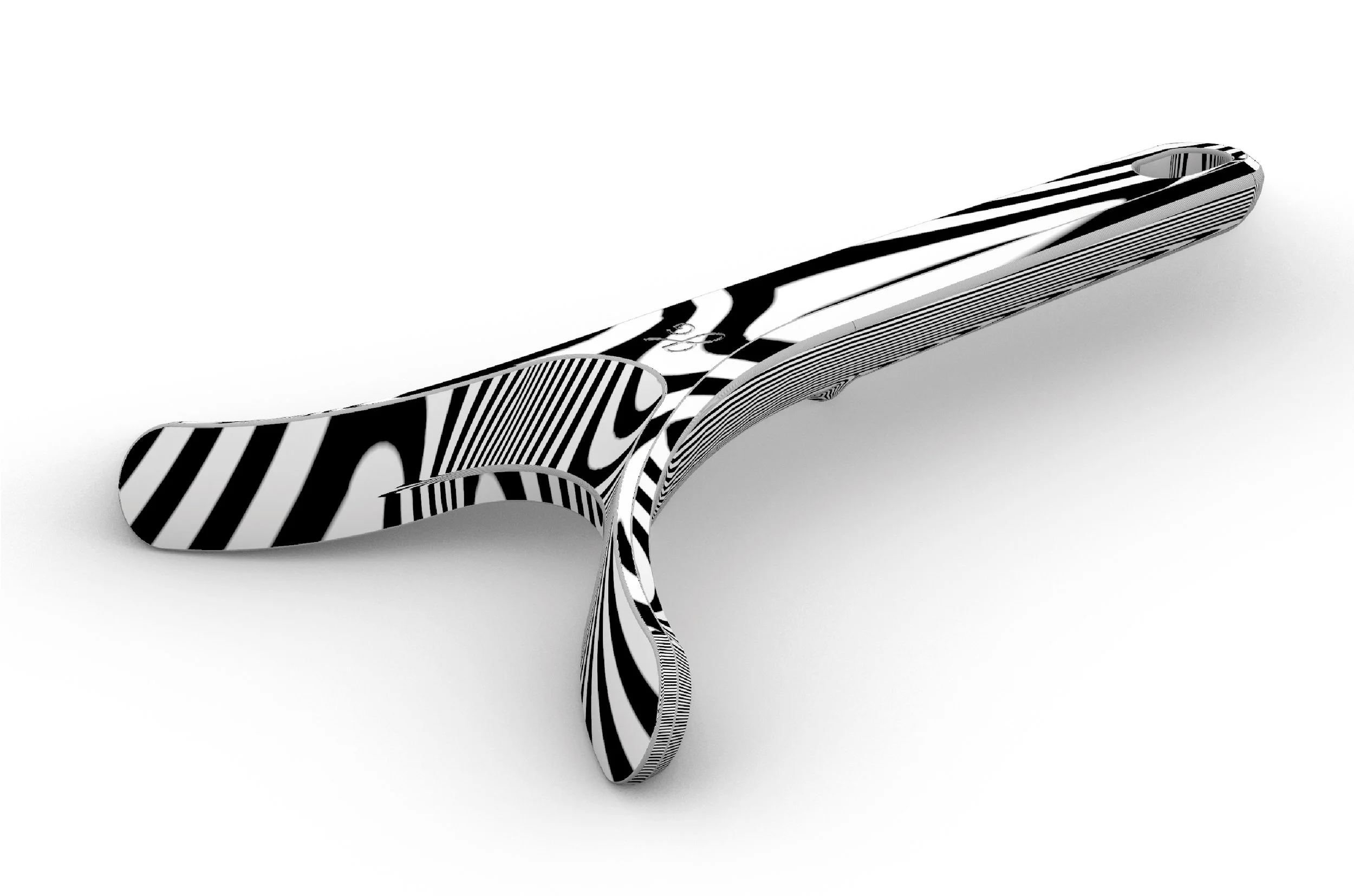

NURBS 3D

Surface modeling is one of my strengths. I carefully refined every curve to meet the company’s aesthetic standards, always paying close attention to detail and quality.

The Weight Matters

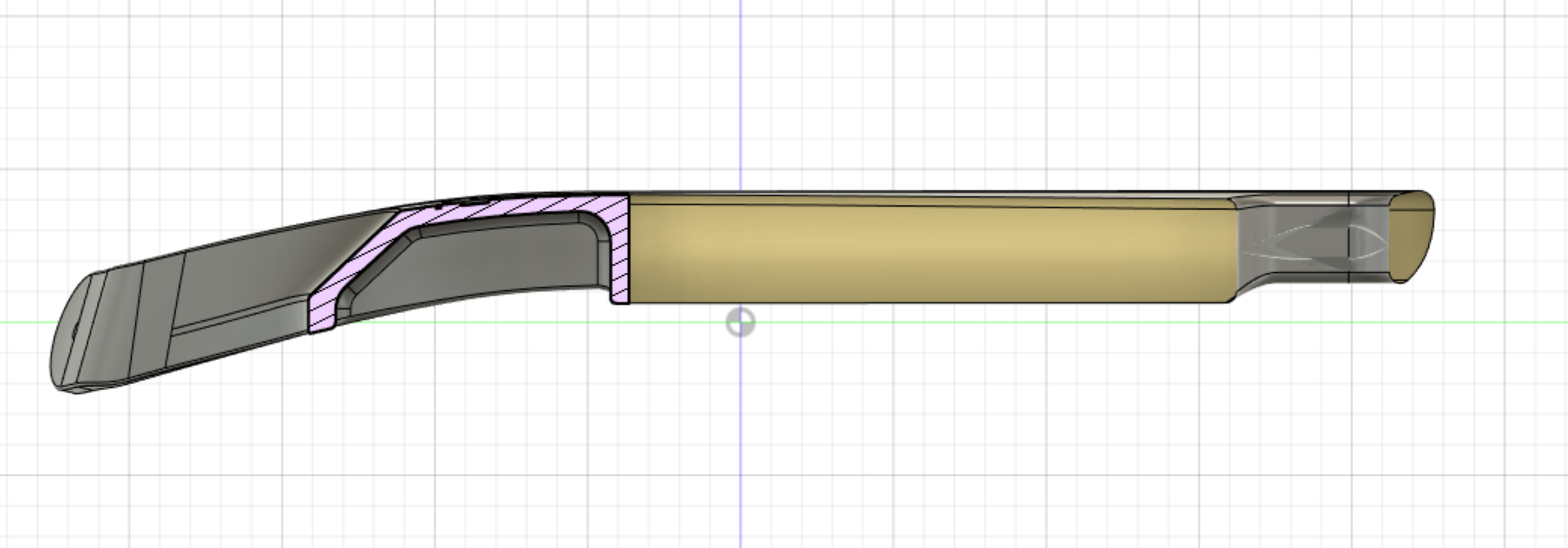

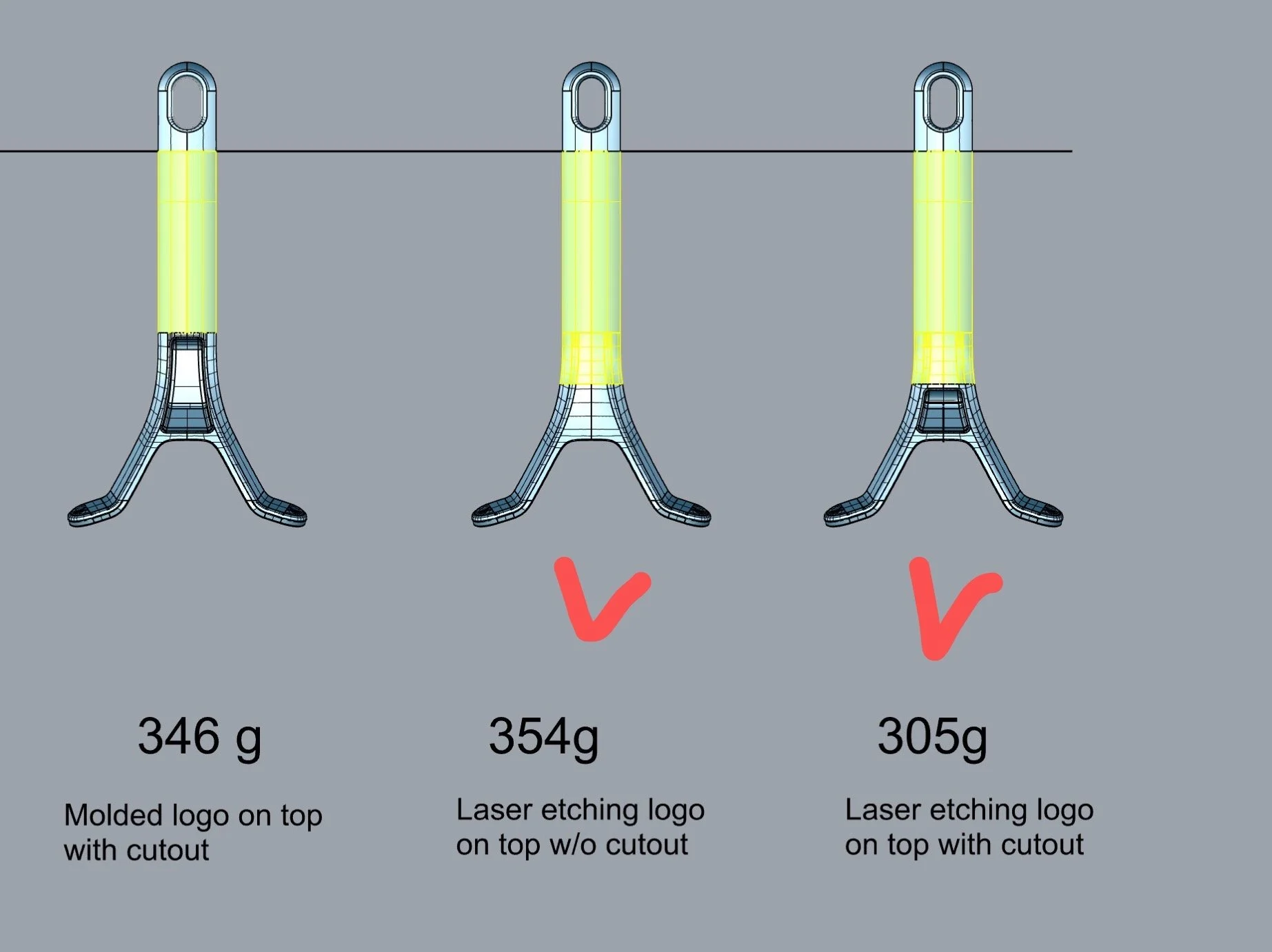

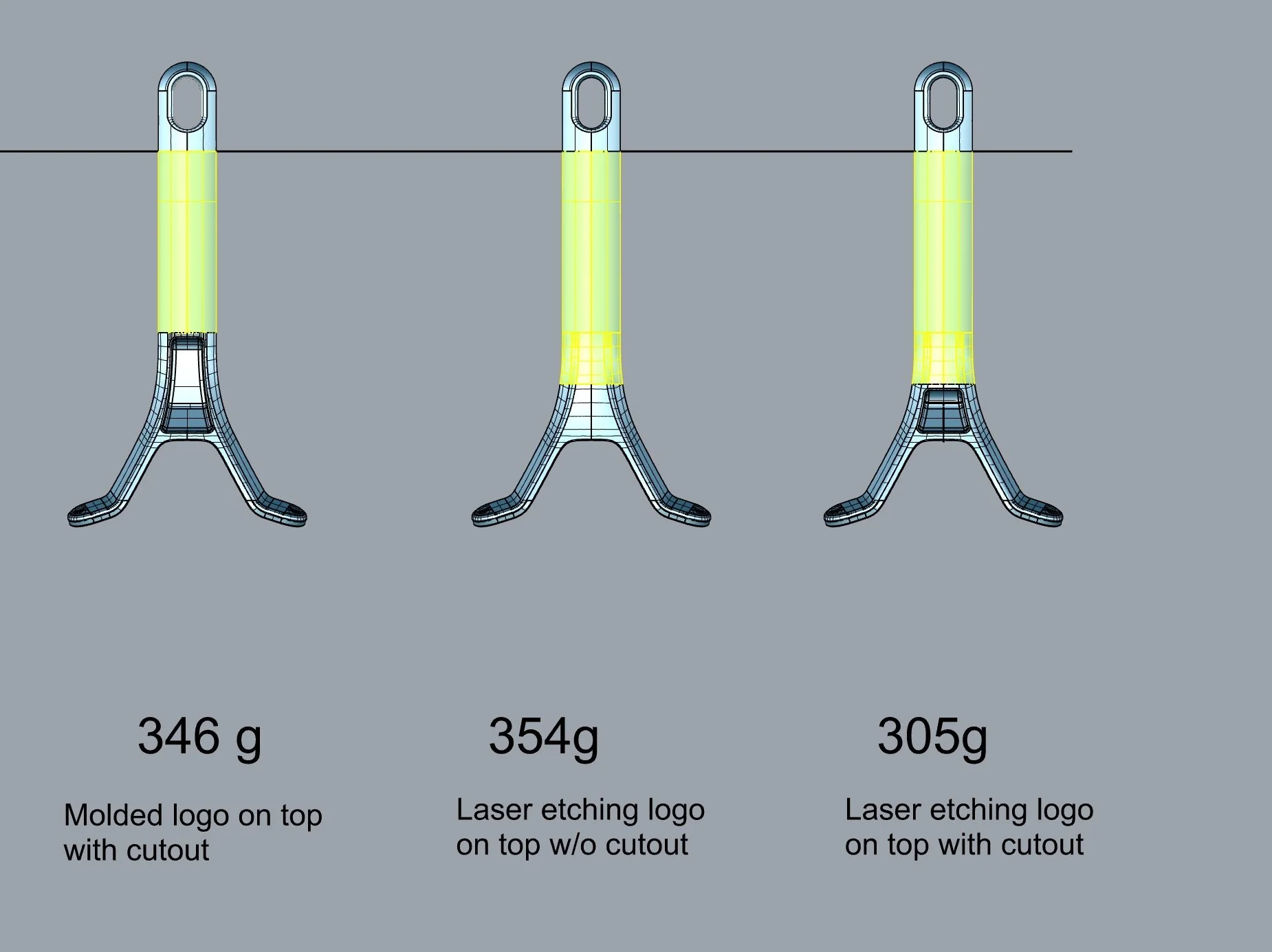

The handle was originally too heavy, which risked making the pan tilt during use — a major concern for functionality. To preserve the design while improving balance, we reduced weight by adjusting the front casting part and adding a groove at the bottom. Using Rhino, we simulated and estimated different material removal options to achieve the ideal weight.

Understand Every Process

It is essential to learn from the factory and work closely with them to find the best solutions. A deep understanding of production details helps push the boundaries of what we can achieve. For this project, the welding was done between two casting parts, followed by hand-sanding of the handle by factory workers to create a refined finish.

Process Matters

We created multiple design iterations and visited factories to fully understand each stage of manufacturing. This included studying how parts are made, evaluating costs, comparing materials, and exploring feasible solutions. Ultimately, we identified the best balance between design intent, functionality, and production efficiency.