LATT SHOPPING TROLLEY

Awarded concept design with 1:1 handcrafted model. Dimension : 58 x 52 x 105 cm/ Feb 2020

Smaller, But Larger Storage

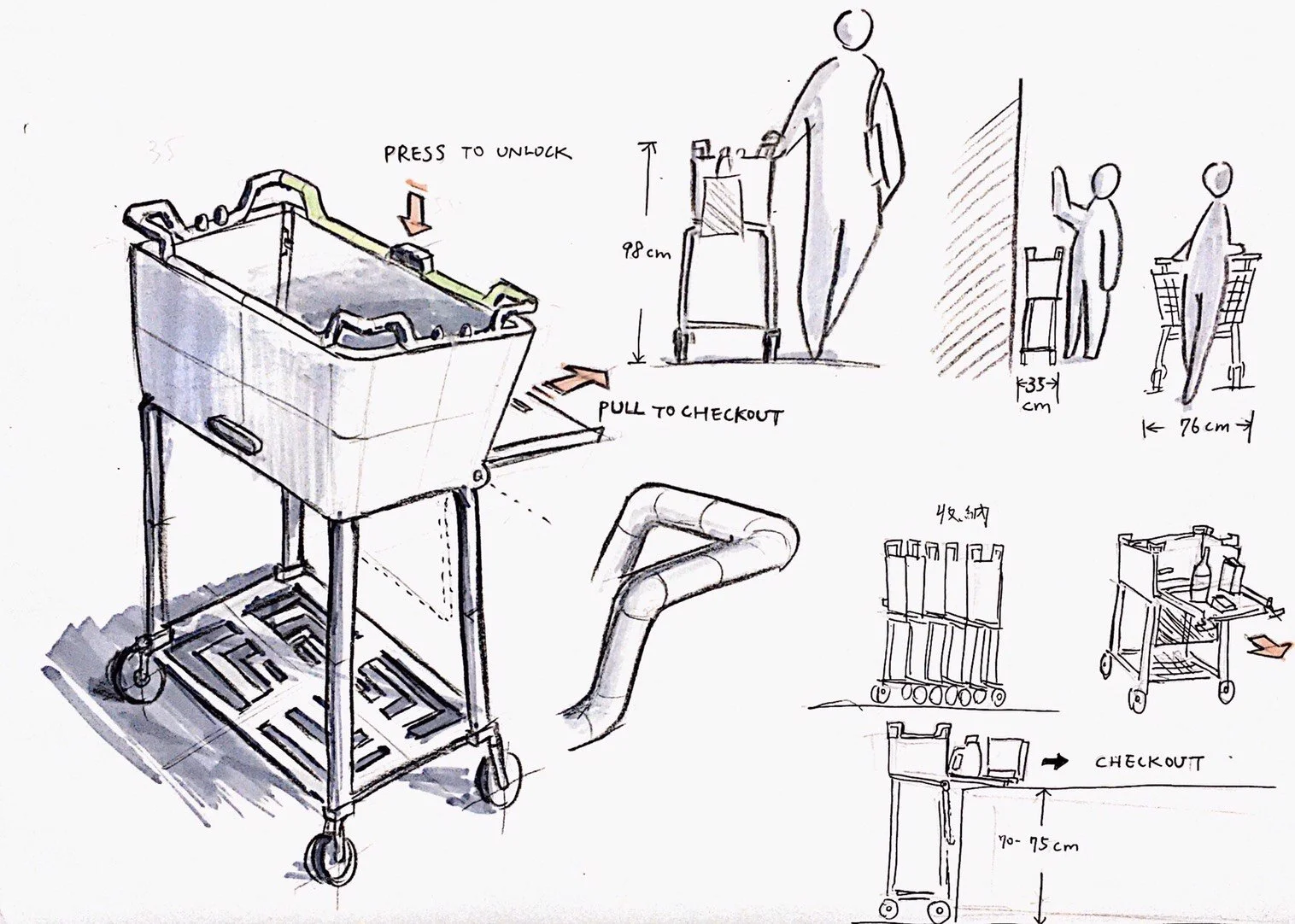

Latt, a shopping trolley with a reduced footprint, features a rear handle that adjusts the height of the basket. This design not only preserves the cart’s full capacity but also assists elderly users by eliminating the need to bend down during checkout. Additionally, its modular structure allows for flexible configurations to meet the needs of different markets.

Improving shopping efficiency in hypermarkets

Users no longer need to bend down to get items

Details

It has a capacity of 80 liters while being two-thirds the size of a standard shopping cart. The basket can be manually raised at checkout, and the multi-stage buckle keeps it securely in place.

Process

I explored several ideas based on common shopping scenarios. Some of the early concepts included:

Modular or Extendable Baskets

The less you buy, the more space you save. One idea was to use modular or extendable baskets on the trolley, allowing users to walk closer and take up less aisle space. However, this concept proved unrealistic as it would make the trolley difficult to maneuver.

Transformable Structure

A trolley that transforms from horizontal to vertical storage to increase capacity. This was dismissed due to potential safety concerns.

Vertical Storage with Matching Heights

This trolley stores items in a vertical way to save space. It can be adjusted to match the height of car trunks or checkout counters, making it easier to move things.

Checkout Transfer Door + Easy Push Handles

This idea includes a small door that lets users move items directly onto the checkout belt. It also has four handles on each corner, so it can be pushed in any direction. However, the design was too complex to use in real life.

From Sketch to Modeling

Hand-sketched and modeled in Creo, with the program used to test stackability.

Other Solutions

I explored several folding methods for the baskets. One idea was inspired by origami, but it posed challenges when folding back. Another involved laser-cut alloy, which looked promising but was too costly. In the end, I chose a simpler and more practical folding method—even if it seemed less exciting.

Hand Prototype

*

Hand Prototype *

For mass production, the material would be stainless steel or zinc-plated iron to prevent rust.

Final 1:1 model fully printed using SLA

1:1 model to evaluate ergonomics

3D-printed 1:10 models to test stackability

1:2 handmade model to study how the basket folds